We make a

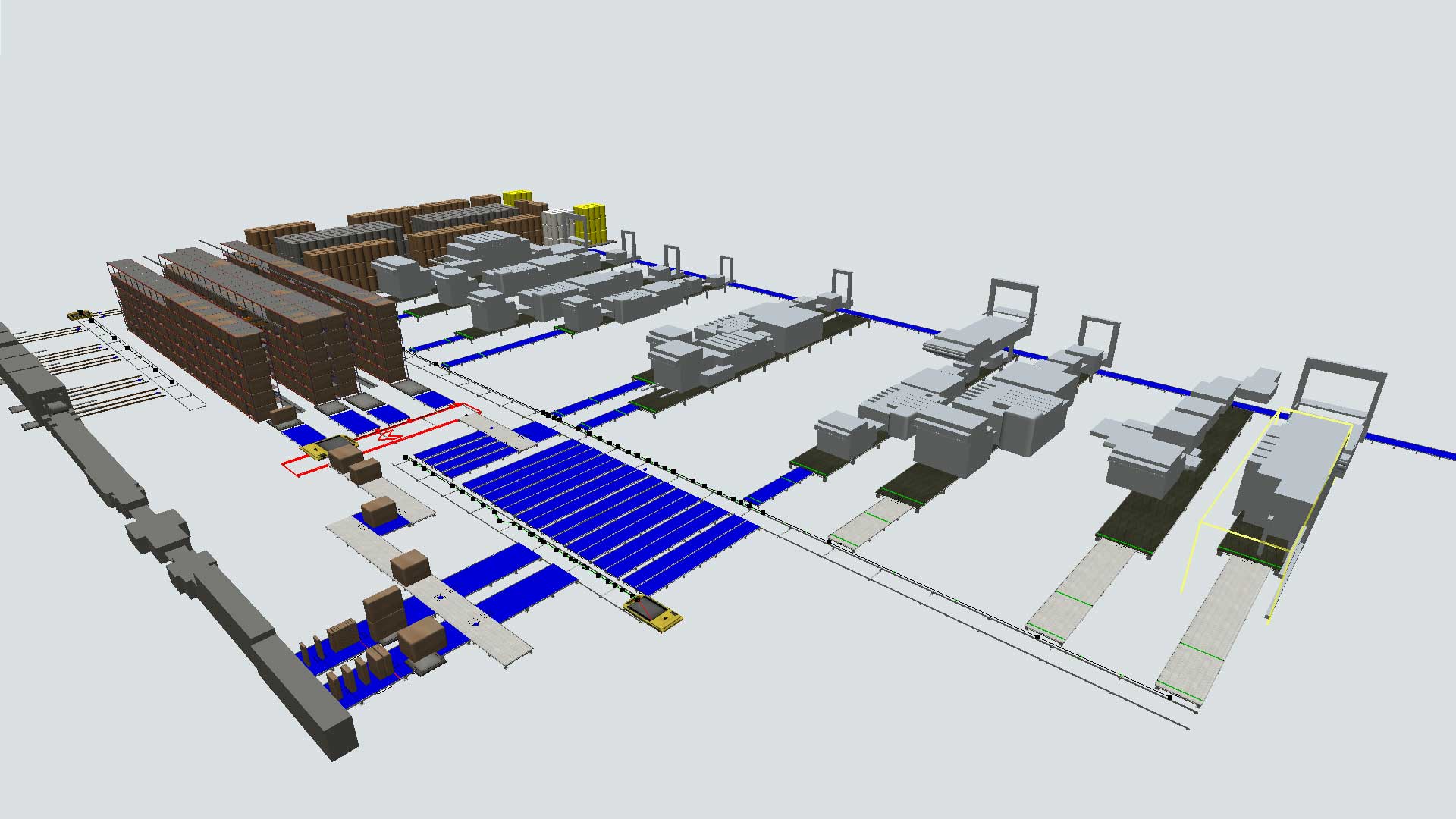

digital twin of your factory

Intralogistics flow predictive software.

We carry out internal logistics efficiency studies in factories using our 3D simulation software. Thanks to our knowledge of the sector and the operation of cardboard production factories, we are able to create a digital twin of your factory based on real data, and achieve an almost exact replica of all the processes. In this way, we can carry out stress tests, simulations, changes in machinery or staff rotation, all in a virtual environment, and later implement them in the real factory.

With accurate information, we can recreate changes in your facilities, such as adding or changing machinery, replacing a flat warehouse with a vertical one or redesigning the current layout. Once these scenarios have been projected, we calculate the improvements they would bring to the annual performance of your factory, providing reliable data on possible future investments.

During the simulation process, new theories can be constantly corrected and tested, which helps you to make the best possible decision.

Areas for Improvement

By testing on the digital twin, we can detect those critical points in the internal board circuit.

With the actual board production data, we can simulate the space required for the efficient operation of both the corrugator and the converter.

Simulation with real data allows us to include new machinery and obtain reliable data on flow and changes in production.

The analysis of flows and storage capacity in addition to the machine park allows us to rethink the planning of orders in the factory.