Vertical warehouses are a very good option for factories or spaces with a considerable height. This way we get to make the most of that height and use a considerably smaller surface. These warehouses are automatically based on the principle of merchandise to man. It is the worker who chooses the product he wants to receive and the stacker crane takes it to the collection point. They consist of a compact design and the products move quickly (according to the load cycle of the used stacker cranes), reducing waiting time and speeding up logistics. For all this to work properly it is necessary to have rigorous stock management.

The vertical warehouse can act as a single work unit in a factory or it can be part of the entire chain logistics process, all through the newest technologies applied according to the needs of each company. The stacker crane will fetch the order automatically (in the case of Warak projects, the stacker crane can handle several orders at the same time). The consumer or customer is increasingly demanding in terms of achieving the highest possible productivity. The vertical warehouse provides advantages at a technical, energy efficiency and even management level.

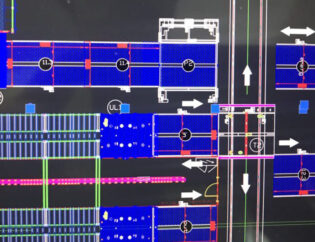

In the design of vertical warehouses there are two key points: the capacity of the rack and the load cycles of the stacker cranes. As for the first, the capacity of the rack will depend mainly on its length and height because it will give us the number of useful cells. But there is another factor that many forget: the depth of the cell. The cell is the result of what happens at the end of the corrugator. Thus, depending on its width and production mix, we will have different results.

It is not true that a 2,800mm wide corrugator always gives us cardboard blocks of 2,800mm cell depth. Only the analysis of the corrugator stack output data will give us the optimal cell depth. As an example, with a 2,800mm corrugator we know there is a 6% rack performance improvement by changing the cell depth to 2,900mm. The mix with the size of the orders and the transformation machinery park are the most important factors in the combination of cardboard stacks for the vertical warehouse. Its variability is less than what we can assume since the current customers of the cardboard factory and the installed machines are factors with little change.

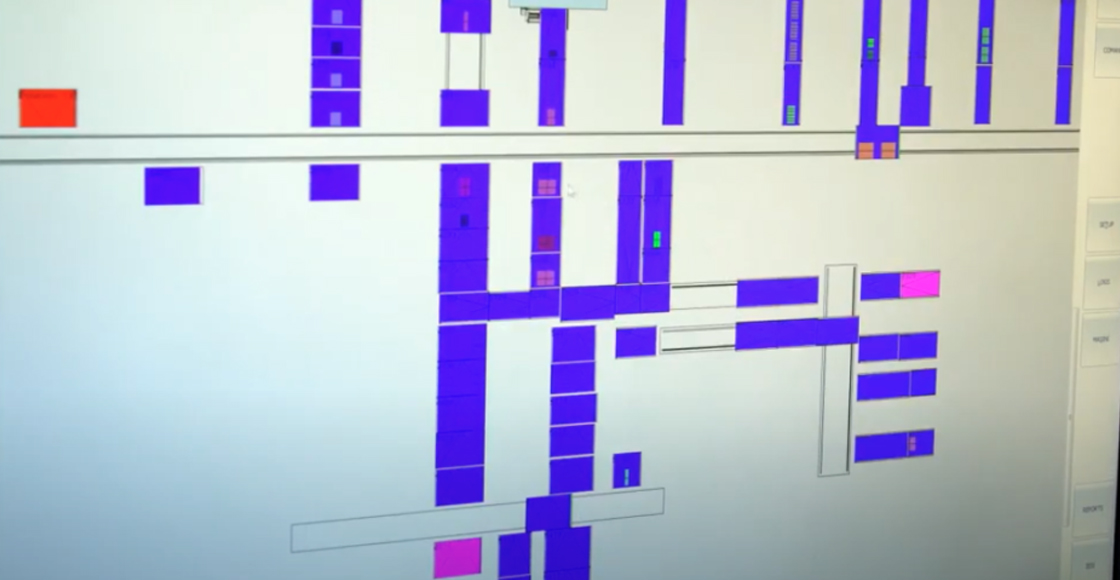

And the conclusions we draw from a possible change are thanks to digital simulation. Knowing how space or the action can change, we can take for granted the result and what we need to apply those improvements.