Packaging and corrugated board companies are constantly looking for ways to reduce costs, optimize resources, and quickly respond to customer demands. One of the most valuable tools in this process is intralogistics simulation, applied to the design and production of corrugated board.

This technology is becoming a cornerstone in packaging engineering, enabling better planning, reducing errors, and minimizing waste.

What is intralogistics simulation in corrugated board?

Intralogistics simulation consists of using specialized software to virtually recreate the characteristics of corrugated board and its behavior under different conditions. In this way, engineers and designers can:

-

Test box and packaging designs without the need to manufacture physical prototypes.

-

Visualize and analyze structural resistance under loads, stacking, or transport.

-

Detect weaknesses in design before reaching production.

-

Validate new proposals more quickly and cost-effectively.

Key benefits of intralogistics simulation

More accurate planning

Intralogistics simulation enables feasibility reports with concrete data, facilitating strategic decision-making. This results in clearer projects from the start, with less uncertainty and better cost and time forecasting.

Reduced design errors

By digitally recreating real conditions, failures are detected that in a traditional phase would only appear during production or packaging use. Avoiding these errors early represents significant savings in time and money.

Less material waste

Each physical prototype implies consumption of board and resources. With simulation, many of these tests are replaced by digital models, reducing waste and promoting a more sustainable process.

Faster innovation

The ability to simulate multiple scenarios allows for quick testing of new ideas and adaptation to market demands, accelerating innovation in packaging design.

Warakblock: Digital Twin and Logistics Efficiency

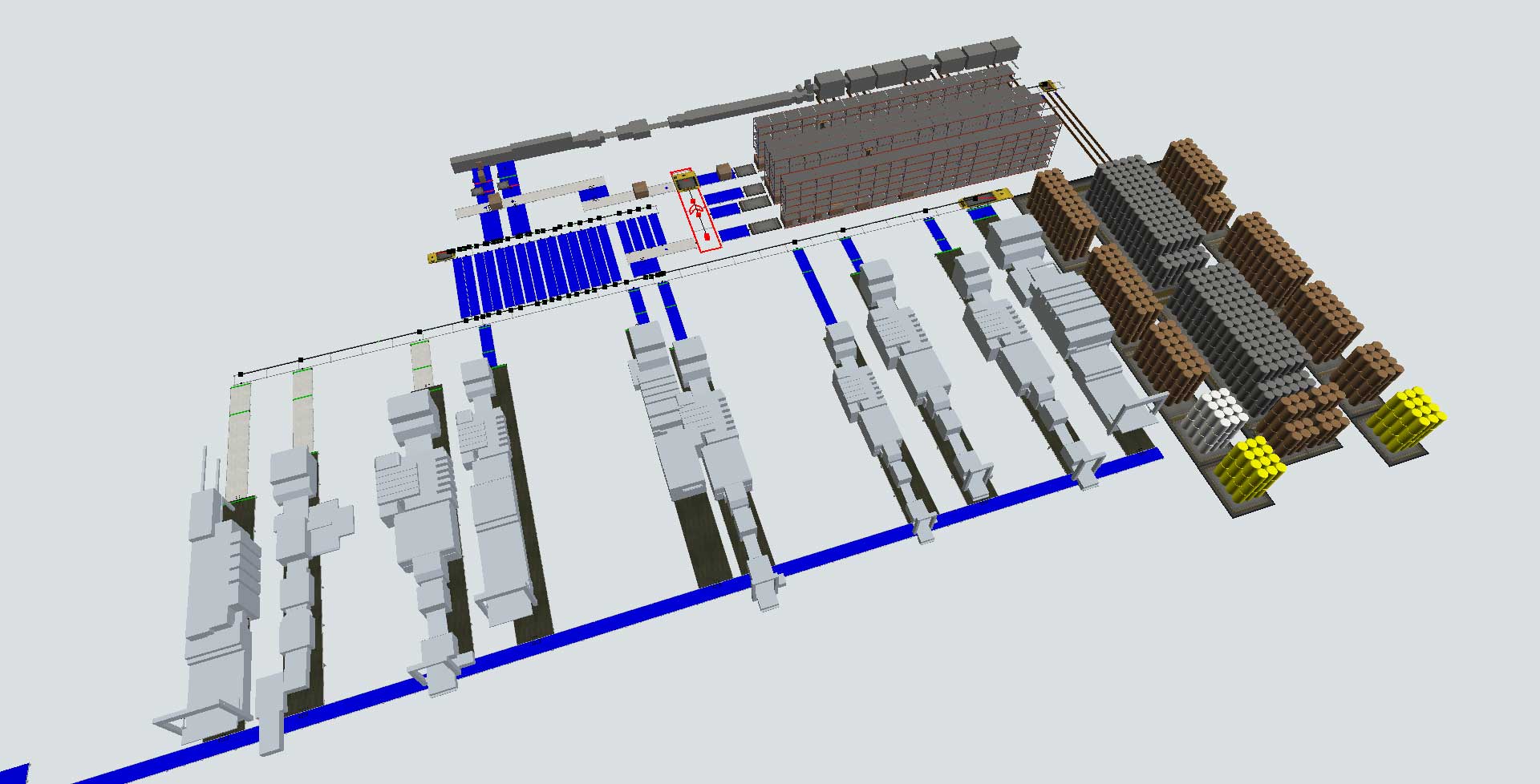

At Warakblock, we take intralogistics simulation one step further with our predictive intralogistics flow software. We not only work on packaging design but also on the complete optimization of the corrugated board factory.

We create a digital twin of your factory, a virtual replica based on real production data. With this tool, it is possible to:

-

Analyze internal logistics efficiency.

-

Carry out stress tests on production processes.

-

Simulate machinery changes, layout redesigns, or staff rotations.

-

Evaluate the impact of new investments before implementing them in the real plant.

Thanks to simulation, companies can make decisions with reliable information, reduce risks, and improve their factory’s annual performance.

Areas of improvement with the digital twin

-

Bottleneck detection: we locate critical points in the internal board circuit to optimize production.

-

Storage capacity: we simulate the space needed for efficient corrugator and conversion operation.

-

New machinery simulation: we virtually incorporate equipment and measure its impact on flows and production capacity.

-

Planning improvements: we analyze internal flows, storage capacity, and machinery to redefine order planning with greater accuracy.

This approach makes the digital twin a strategic tool that detects problems and offers practical, measurable solutions.

With solutions like those from Warakblock, innovation is not only visible in design. The entire production and logistics chain is improved, efficiency increases, and each investment ensures real value for the factory.